Precision Casting Stainless Steel Casting Impeller

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 5 Ton |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 5 Ton |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin |

Brand: A&M Manufacturing Company Ltd

| Selling Units | : | Ton |

| Package Type | : | Export standard packing |

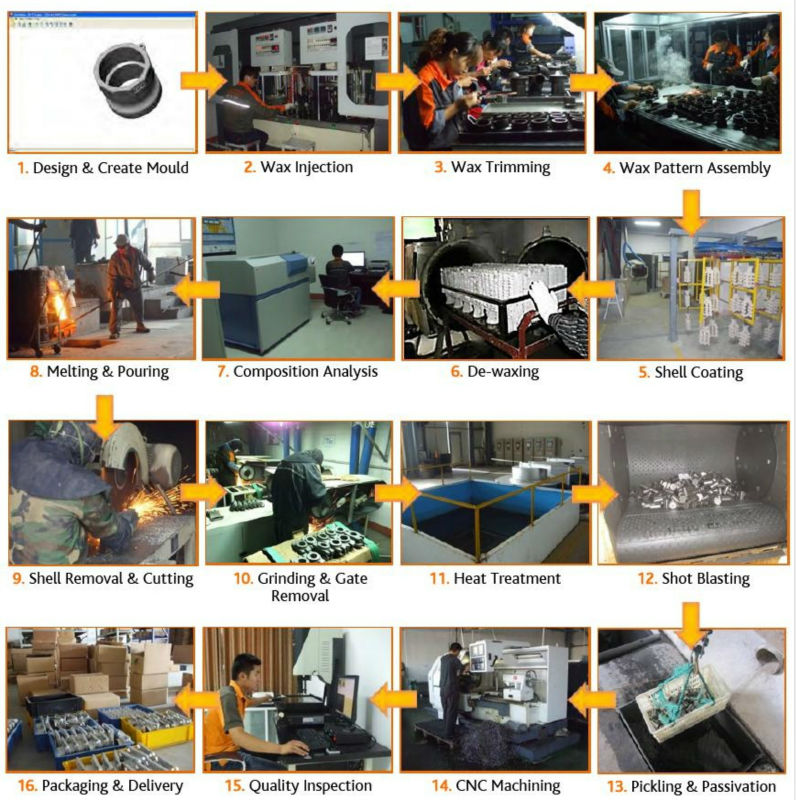

At A & M Manufacturing Company Ltd, we possess extensive capabilities in producing stainless steel components using the Investment Casting technique coupled with Precision Machining. With a commitment to quality and precision, we offer a comprehensive range of services tailored to meet our customers' diverse needs.

At A & M Manufacturing Company Ltd, we understand that every project is unique. That's why we offer customisation and flexibility in our manufacturing processes to accommodate our customers' specific needs and requirements. From prototype development to mass production, we work closely with our customers to deliver stainless steel components that exceed expectations.

Based in the UK, A & M Manufacturing Company Ltd has over 30 years of invaluable experience in the foundry and general metalworking industry. Our years of innovation and experience have firmly established us as a leader in the field. With over 10 years of dedicated effort in establishing strong relationships with China and Taiwan, we have built an extensive and robust manufacturing network. This network not only enhances our extreme competitiveness but also empowers us to consistently deliver parts of uncompromising quality. Our commitment to excellence and our extensive manufacturing network make us your ideal partner for precision manufacturing solutions.

We take pride in our specialisation across a diverse spectrum of manufacturing processes, encompassing all types of casting techniques. Our exceptional expertise shines through in our mastery of investment casting, sand casting, shell mould casting, and gravity die casting. Beyond casting services, our capabilities extend to fabrication, forging, stamping, and precision machining from solid parts. Whether you require parts in small, medium, or large volumes, we have the flexibility to cater to your needs, ranging from class 1 aerospace castings to finely crafted machined components. Moreover, our commitment to excellence extends to the design stage, where we offer valuable guidance on both shape and material specifications.

As a professional provider of manufacturing solutions and services, we go beyond offering casting, forging, and other metalworking services. Our services include in-house tooling design and product concept consultancy. Our team of experienced engineers has tackled a wide array of complex and challenging projects spanning various industries and applications. Whether you approach us with concepts, samples, or drawings, we have the capability to design and manufacture suitable tools to meet your manufacturing needs. Regardless of the complexity of your projects, A & M Manufacturing Company Ltd can effectively provide you with the best solution, ensuring the required tolerances while maintaining cost-effectiveness.

In addition to all the manufacturing solutions and services we provide, we offer flexible supply options to our customers owing to our UK stock holding facilities, ensuring timely and reliable delivery of your products, solidifying our position as your long-term, trustworthy partner. For more information, please don’t hesitate to contact us.

As a professional manufacturing solutions provider and product supplier, we offer top-quality products and also oversee the entire manufacturing process. From the initial steps to the final stages, we ensure that every aspect of the products meets customers’ requirements. This includes design concepts, drawings, dimensions, chemical attributes, surface finish, and various other aspects, all the way to the finished products delivered to the customers’ doorsteps. We are fully equipped with the most advanced inspection facilities, including Coordinate Measuring Machines (CMMs), X-ray and CT scanning, Non-Destructive Testing (NDT), Ultrasonic detectors, and many more.

At A & M Manufacturing, there’s never a shadow of doubt when we send out a product. We consistently uphold high-quality standards, and our risk-management approach extends to all our valued customers, a source of our pride.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.